A beautiful beach of the past Kings on the Kona coast on the big island of Hawaii is shown

here just to get you in the mood for a cruise, swim or snorkel with the friendly fish and the

giant sea-turtles or just a great, great place to get away. Sea kayaking is a great sport here.

here just to get you in the mood for a cruise, swim or snorkel with the friendly fish and the

giant sea-turtles or just a great, great place to get away. Sea kayaking is a great sport here.

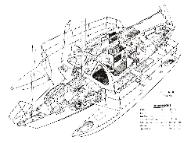

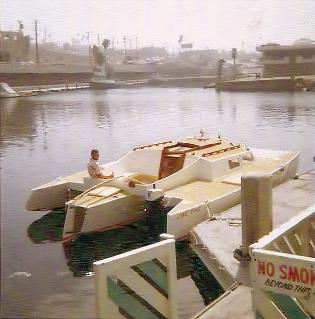

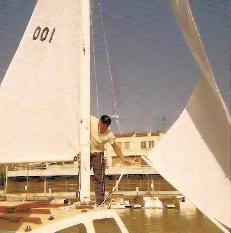

These photographs have nothing to do with a

sea going kayak but are presented here for

the visual presentation of yet another

multi-hull sailboat under construction (the

Kiwi-18) which represents the latest in

simplest cold molded construction

techniques with epoxy and mahogany strip

veneer composite construction. This

technique lends itself very well to wooden

aircraft construction and is extremely easy

and forgiving to the beginner who wants to

build a light, very stiff and strong craft.

Epoxy used is the West System. Refer to the

Links tool bar in the left window.

sea going kayak but are presented here for

the visual presentation of yet another

multi-hull sailboat under construction (the

Kiwi-18) which represents the latest in

simplest cold molded construction

techniques with epoxy and mahogany strip

veneer composite construction. This

technique lends itself very well to wooden

aircraft construction and is extremely easy

and forgiving to the beginner who wants to

build a light, very stiff and strong craft.

Epoxy used is the West System. Refer to the

Links tool bar in the left window.

Notice the compound curves that can be achieved from

using flat veneer strips. The two photos shown here

are that of a modern ocean going 18 foot multi- hull

outrigger sail boat that is designed as a prototype to

exactly duplicate the weight of a production version to

be manufactured from all fiberglass and polyester or

vinyl composite resins. The total skin thickness is only

0.25 inches (6 mm) and is far stiffer than those made

from fiberglass and polyester. No screws or nails

have been used in the construction.

using flat veneer strips. The two photos shown here

are that of a modern ocean going 18 foot multi- hull

outrigger sail boat that is designed as a prototype to

exactly duplicate the weight of a production version to

be manufactured from all fiberglass and polyester or

vinyl composite resins. The total skin thickness is only

0.25 inches (6 mm) and is far stiffer than those made

from fiberglass and polyester. No screws or nails

have been used in the construction.

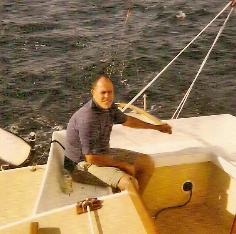

As shown to the left, torture

bending at its worst. The saying is

generally "what ever works with

what you have". The strength of the

epoxy is very much evident. Notice

the prepared deck scarf joints

ready for the fore deck attachment.

bending at its worst. The saying is

generally "what ever works with

what you have". The strength of the

epoxy is very much evident. Notice

the prepared deck scarf joints

ready for the fore deck attachment.

| The aft deck has been installed and the water tight lazarette can be seen for access to the spade rudder bearing, rudder removal shaft pin and storage area. This craft is totally epoxy bonded and has an outside color finish coating on top of the epoxy with extremely hard linear polyurethane. The spade rudder can just be seen below the hull. |

| SeaKayak - 20/2 Line drawings for the SeaKayak - 20/2, a 20 foot long 2- place |

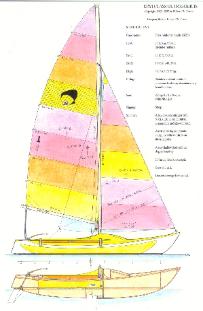

To the trained eye, the performance can be observed.

To those who need a specifications data chart, one is

presented from the drawing as shown to the right.

The construction method is not to be found in kayaks that

are offered from kit manufacturers. It is not the flat panel

Strip-built (SB) and Stitch & Glue (S&G) method.

Construction is closer to the Strip-built method but

layered in a different manner that provides contoured

stiffness. Thin plywood veneer or fine clear grain cedar

strips may be used. For abrasion resistance, fiberglass

may be added to the outside but is generally not needed

as the resin does add weight.

These are truly fun craft to occupy and propel yourself

and a friend through the water. It is a very gratifying form

of accomplishment when one completes the construction

and does the water ventures. The dolphins really do

come up to your kayak to see you if you remain very still.

My wife and I witnessed this when we kayaked across

Kealakekua Bay on the Big Island of Hawaii where the

famous English explorer Captain James Cook, R.N. was

killed by the natives. A white colored monolithic

monument was constructed there in 1874 to honor the

man for his fabulous explorations and discoveries. There

is a bronze plaque just at water level (below at high tide)

marking the exact spot where he met his unfortunate

fate. Don't forget to wear rubber snorkel or boating foot

wear as the sharp coral will cut your feet.

To those who need a specifications data chart, one is

presented from the drawing as shown to the right.

The construction method is not to be found in kayaks that

are offered from kit manufacturers. It is not the flat panel

Strip-built (SB) and Stitch & Glue (S&G) method.

Construction is closer to the Strip-built method but

layered in a different manner that provides contoured

stiffness. Thin plywood veneer or fine clear grain cedar

strips may be used. For abrasion resistance, fiberglass

may be added to the outside but is generally not needed

as the resin does add weight.

These are truly fun craft to occupy and propel yourself

and a friend through the water. It is a very gratifying form

of accomplishment when one completes the construction

and does the water ventures. The dolphins really do

come up to your kayak to see you if you remain very still.

My wife and I witnessed this when we kayaked across

Kealakekua Bay on the Big Island of Hawaii where the

famous English explorer Captain James Cook, R.N. was

killed by the natives. A white colored monolithic

monument was constructed there in 1874 to honor the

man for his fabulous explorations and discoveries. There

is a bronze plaque just at water level (below at high tide)

marking the exact spot where he met his unfortunate

fate. Don't forget to wear rubber snorkel or boating foot

wear as the sharp coral will cut your feet.

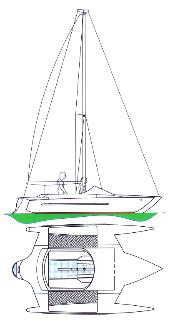

To the right is a proof of lines concept model for an 21

foot ( l.o.a.), ocean sailing, 2- place wood and fiberglass

trimaran day sailor with forward cutty for one person to

get out of bad weather.

A very comfortable area for beach camping as well.

Photos to the right.

The model has stringers only for viewing the shape. The

real construction would have none, like the Kiwi 18 shown

above. Floats (amas) would fold down for trailering and

the mast is self rotating. Safety netting would be between

the main hull seating and each ama. Forward netting can

be optional as this has turned out very beneficial in

previous trimarans.

The interesting thing about trimarans, besides being very

fast and stable, is the main hull volume increases to the

cube power (cubic feet of inside space) for every foot in

length. This provides lots of comfort because of the rapid

increase in space for occupants and amenities.

foot ( l.o.a.), ocean sailing, 2- place wood and fiberglass

trimaran day sailor with forward cutty for one person to

get out of bad weather.

A very comfortable area for beach camping as well.

Photos to the right.

The model has stringers only for viewing the shape. The

real construction would have none, like the Kiwi 18 shown

above. Floats (amas) would fold down for trailering and

the mast is self rotating. Safety netting would be between

the main hull seating and each ama. Forward netting can

be optional as this has turned out very beneficial in

previous trimarans.

The interesting thing about trimarans, besides being very

fast and stable, is the main hull volume increases to the

cube power (cubic feet of inside space) for every foot in

length. This provides lots of comfort because of the rapid

increase in space for occupants and amenities.

Proof of lines concept

|

|

| The Shape of Things o Come Have Been Here for Some Time The Marine Division section shows the similarity between aircraft and boat construction. Also, check out the Gougeon Brothers, Inc. "West System" in the Links section. Their book on boat construction is the best on the market and an absolute must for wood aircraft builders. Much more usable than what the EAA sells. For a large bound book, the price is very easy on your pocket at $39.95 The Gougeon Brothers on Boat Construction Hardcover-406 pages. Decades of experience building with wood and epoxy are compiled in this 5th edition, completed in 2005. New and updated material is combined with proven technology in a revised layout for navigation. Extensive chapters on hardware bonding, construction methods, safety and tools are described with the aid of hundreds of detailed illustrations and photographs. Used as a textbook in boatbuilding schools. Over 100,000 copies in print. |

| Copyright © 2000- 2014 by Richard W. Fraser All Rights Reserved |

| Click on picture above to enlarge and again click on the enlargement to sharpen with some viewers. |

Marine Division

| Including Arthur Piver's Original Modern Sailboats Catalog of Designs |

Page 1

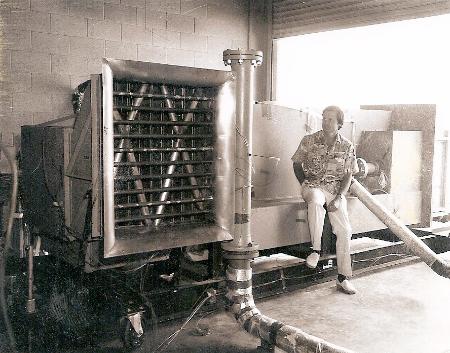

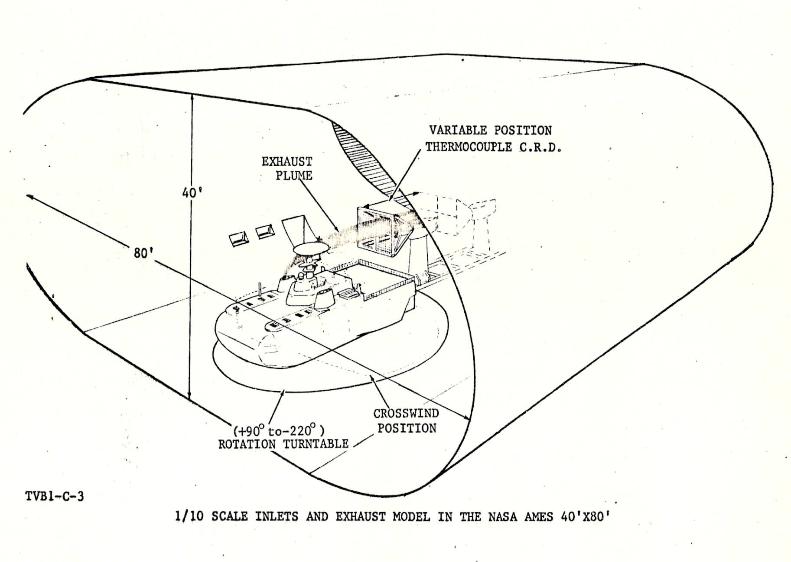

| Rohr Industries, Inc, Marine Division US Navy Surface Effect Ship Past Developments |

|

| ||||||||||||||||||||||||||||||||||||

| 3KSES Surface Effect Ship at bottom of page |

|

|

|

Kiwi-18 above - compound curves can be

accomplished

accomplished

Kiwi 18 Sail Plan

FRASER AERO TECHNOLOGY COMPANY |