Sky Pup News

Newsletter No. 4 July, 1984)

Pennsylvania Sky Pup

Rotax Power

Beware of Bonding

Building Tips

Special Bulletin: Heavy Pups due to excess varnish.

-------------------------------------------------

SKY PUP NEWS is a quarterly newsletter for builders of the Sport Flight “Sky Pup”. The purpose of the newsletter is to make builders aware of revisions, suggestions and ideas which are brought to our attention. We solicit your input in the form of photos, ideas, and time or money-saving tips. Please share your progress and comments by sending them to Sport Flight, c/o NEWSLETTER.

Subscriptions to SKY PUP NEWS are $12.00/year (foreign please add $6.00, Canadian please add $2.00). All subscriptions are based on a calendar year, i.e. not from date ordered. For example, if you order subscription in June of 1984, you will receive the January and April 1984 issues immediately, and the July an October issues when they are printed. Please use your plans Serial Number in all correspondence with Spor Flight, and specify which calendar year your subscription fee is for.

Pennsylvania Sky Pup

This issue’s featured Pup is SN 1863 which was constructed in about six months of spare time effort by Terry Rockwell of Susquehannah, PA. Total building cost for the per-plans project is reported as $2200, although Terry says he could build another one for a lot less.

Terry was assisted during the construction by his father, an eleven year old son, and a very supportive wife. The bird is black and orange (Uh…Terry…about your choice of colors…) and is Cuyuna powered. SN 1863 is shown with its builder in the photos below. The one on the right is Terry posing with his clipped shirt after his first solo!

Terry had an interesting experience on his very first test hop which rivals about any first flight story we’v heard yet. It seems that he was at the airfield doing some taxi and crowhop work when he found himself airborne and committed to go around. On climbout, the belt reduction system decided to start slipping with resultant loss of power (even though the engine was still running to beat the band!). Since the surrounding country was very heavily wooded, Terry aimed the Pup toward the only open area in sight—the Susquehanna River! He underflew a set of powerlines spanning the river, and “ditched” the bird in the water at what he hoped was a reasonable swimming distance from an island. To his surprise, the water was less than a foot deep, and he made a good landing with the aircraft remaining upright. Terry pulled the Pup out of the water and onto the island to dry off a bit while he contemplated his next move.

As luck would have it, a couple of friends were returning to the airfield in a Cessna 150 and spotted the damp duo on the island. Surmising that possibly Terry was in need of some assistance, the friends hastened to the shore of the river with a borrowed rowboat and paddled over to the island. The three men hoisted the soggy Pup onto the boat and floated back down the river to the airfield where the Pup was returned to its hangar. After a thorough drying and close inspection, the bird was found to be no worse for the wear, and the cause of the belt slippage was remedied. Terry has since logged about a dozen flights without further incident.

Terry is a fledgling pilot with most of his experience in R/C models and flight simulators—he works for LINK. He got some dual in a Cessna 150 and practiced slow flying and rudder-only turns in preparation for the Pup’s two-axis control system. He reports the Pup is very easy to fly, and that the project was a very enjoyable one.

Rotax Power

The Sky Pup prototype has been flight tested with the Rotax 277 engine over the last two months. The following are our observations of the testing.

Installation of the Rotax is simple, but does differ from the Cuyuna installation in that the bottom of the Rotax is not a flat surface which can be bolted directly to the engine breadboard. The integral gear drive is in the upright position to allow as much prop clearance as possible. Rotax installation drawings are available for Sport Flight for $10.00 ppd.

Performance with this engine is quite remarkable, with 100-foot take-off rolls and 1000 fpm climb rates in sea level conditions. Torque is noticeable in climb—probably because it is opposite that normally encountered since the prop is left-hand rotating. Vibration levels are a little higher than with the Cuyuna at all RPM’s, but no evidence of vibration-induced problems have been found.

Since the installed weight is about two pounds greater than that of the Cuyuna, the Rotax may be out of the question for those builders who are fighting to stay under the 400 lb gross weight limit. The Pup will meet the speed limits of Part 103.7 with one knot to spare by both flight testing and calculated performance criteria.

Perhaps more important than the “legal” speed limitations, however, are the speed limitations of the design envelope. The Pup will encounter its highest airframe loads under gust conditions at high speeds. The higher the airspeed, the more severe the resulting load. Like many relatively “clean” aircraft, the Pup is capable of going faster than it is safe to operate in turbulent conditions. REGARDLESS OF ENGINE USED, THE PLAN SPECIFIED OPERATING SPEEDS MUST BE STRICTLY FOLLOWED TO AVOID POSSIBLE STRUCTURAL PROBLEMS. When in rough air, it is the PILOT’S RESPONSIBILITY TO SLOW DOWN.

One possibility for reducing the weight of the Rotax installation might be to disregard use of the factory exhaust system, and replace it with an appropriate length of flex tubing and a motorcycle-type silencer. Some power loss would no doubt result, but the Rotax has plenty of that to spare, and that stock exhaust system is quite heavy.

Sport Flight can provide a complete package, including engine, carburetor, exhaust, reduction drive, fuel pump, tool kit, manual, and Culver propeller for $1140. This includes shipping costs to points in the continental U.S. Please contact Sport Flight for more details and ordering or delivery information.

Beware of Bonding

Recently, we were contacted by a builder who felt uneasy about the integrity of the bonds between the spar caps and the foam cores of his wing spar assemblies. He stated that he was unsure of the bonds because they were made in a cold shop during the winter, and no epoxy “squeezed out” of the bondline when the spar caps were clamped into position.

We advised the builder of a method for proof-loading the spar assemblies, which he did, inadvertently loading them beyond limit load. The spars failed when the spar caps delaminated from the foam cores at a load level of 69% ultimate, which corresponds to about 4 g’s. Inspection revealed that substantial voids in the bondline had resulted from epoxy which was simply too “thick” to spread and penetrate into the wood fibers. By the photos that he sent us, the bonds appeared to be about 40% void. This spar might have given the builder many years of trouble free service, but his initial hunch about the bonds was correct.

All builders should exercise extreme care and follow manufacturer’s directions on temperature limitations, pot life, and etc. religiously, especially when making bonds as critical to the strength of the airframe as the one mentioned above. Use of commercially available epoxies which are not specifically recommended for wood structures should be avoided. When in doubt, rely on epoxies commonly used in aircraft construction.

Building Tips

The following are some of the suggestions and tips which have been sent to us by Sky Pup builders. Pleas send us any others you have found to be helpful.

1. When using toothpicks to temporarily “stake” together foam parts which are being bonded, waxing or soaping the toothpicks will eliminate the need to remove them before the bond has fully cured.

2. Obtaining proper alignment of the wing attach fittings during the process of bonding the bearing block into the wing spar cores is probably the most difficult step in the construction of the Pup. The following method has been suggested by several builders, and appears to be the most foolproof we’ve heard of yet.

The blocks and fittings are made to completion with the required accuracy. The fittings are the temporarily bolted to the blocks in their respective locations. Each block/fitting assembly is the attached to its mate with the main 3/8” attach bolt. The spar cores are set up in their correct relative location to one another, and the blocks are inlaid simultaneously. The end result is that th centersection and outboard wing spars are attached via the 3/8” bolts, before the spar caps are added. Obviously, the spars can be disjoined while the spar caps are bonded in place for ease of handling. The only caution which should be mentioned with this method is that the assembled centersection an outboard spars should be handled gently to prevent damage to the bonds between the bearing block and the foam cores before the caps are in place.

3. An easy method of profiling the nose ribs of the wing at the locations of the D-skin joints is to affix small piece of 1/16” plywood onto the straightedge used to block sand the ribs. With sandpaper on the lower surface, the nose rib will be profiled exactly 1/16” under the contour of the adjacent ribs.

4. Many builders have asked if the outer surface of the D-skin should be varnished before the fabric is attached, or if the wood should be left bare for better contact cement adhesion. The wood should be varnished for moisture protection. If the varnish has made a slick surface that the cement is reluctant to stick to, rough it up slightly with steel wool before beginning the covering process.

Note the following Addendum to the July 1984 issue:

July 27, 1984

SPECIAL BULLETIN

Sky Pup News

Newsletter No. 3 April, 1984

First Nebraska Pup Flies

Miscellaneous

Oshkosh Plans

Building Tips

Changes & Modification

Steerable Tailwheel Option

-------------------------------------------------

SKY PUP NEWS is a quarterly newsletter for builders of the Sport Flight “Sky Pup”. The purpose of the newsletter is to make builders aware of revisions, suggestions and ideas which are brought to our attention. We solicit your input in the form of photos, ideas, and time or money-saving tips. Please share your progres and comments by sending them to Sport Flight, c/o NEWSLETTER.

Subscriptions to SKY PUP NEWS are $12.00/year (foreign please add $6.00, Canadian please add $2.00). Al subscriptions are based on a calendar year, i.e. not from date ordered. For example, if you order subscription in June of 1984, you will receive the January and April 1984 issues immediately, and the July an October issues when they are printed. This will insure that subscribers will receive all information which was included during that year’s newsletters.

Please use your plans Serial Number in all correspondence with Sport Flight. Thank you!

First Nebraska Pup Flies

Don Kerbel, of Morrill, Nebraska, finished his Sky Pup (SN1850) on January 20 of this year after two month and two weeks of building time. Don used the spare time during his winter season as a farmer to construct the Pup which has logged 22 flight hours at the time of this writing. The photos below show SN1850 in a field on Don’s place. (City dwellers, eat your hearts out!). Transporting the bird was not a consideration to Don since he has lots of flying room right out his back door.

Don reports a building time of 425 hours, and a total cost of $2250 which includes $445 in phone calls, spares,

and miscellaneous costs associated with the project. His Pup is two-tone blue, and is very “stock” with the exception of a steerable tailwheel and some minor internal changes. The Cuyuna 215 is fitted with Competition Aircraft ULTRA-PROP of 59 inch diameter, and 12°pitch blocks. Don says the performance is very lively with this combination, and claims a cruise speed in the high 50’s, with a climb rate of 600 fpm. (Morrill is 4500 feet above sea level.)

The Pup was Don’s first airplane building project, but he is a licensed private pilot with about 300 hours in Cessnas. He bought an extra prop by attempting to taxi the Pup around the yard without the wings on. (Beware—it’s a little nose heavy that way!) Don has also incurred some light damage in a landing through a electric fence which he says “was no fault of the plane”. Don says he thoroughly enjoyed the project, and could build a second Pup for considerably less money. He felt that some details in the plans were a little tough to “cipher out”, and that the cockpit could stand to be widened and lengthened a couple of inches. Don says his Pup flies beautifully, and that his biggest surprise was how well the aircraft responded in roll through the rudder input.

Miscellaneous

The two vendors below are the only authorized distributors of Sky Pup materials kits:

Wicks Aircraft Supply 410 Pine St.

Highland, IL 62249

(618) 654-7447

Aircraft Spruce and Specialty

Box 424

Fullerton, CA 92632

(714) 870-7551

Remember to always specify that you are building a Sky Pup when ordering materials from them.

Sport Flight has just received a Rotax 277 “free air” engine for testing on the Sky Pup. Results of the installation and flight-testing should be well documented in a couple of months. After flying some other ultralights powered with this engine, our concern is that it might have a little too much power for the Pup.

A couple of items missing in the construction plans have been brought to our attention. The material callout for the leading edge strip and trailing edges were inadvertently omitted. The leading edge strip should be labeled “softwood” per the definition in the text, and the trailing edge should be fir. Also, on sheet 8 of the construction drawings, there are a couple of reference lines and dimensions which do not relate to anything and have caused confusion. Particularly, in the front view of the leading attach joint, the dimension “2 3/16” and its related dimension lines should be ignored.

Oshkosh Plans

We are planning to attend both Oshkosh Fly-Ins this year. The EAA ULTRALIGHT ’84 Convention is schedule for June 15-17, and EAA OSHKOSH ’84 (the BIG one) is scheduled for July 28 through August 4.

In an effort to get as many Pups together at one time as possible, we are soliciting input from Pup builder who think they may be taking their birds to either event. The Ultralight meet will be a smaller event, and would allow more time for “shooting the breeze” and flying in uncrowded skies. Please let us know which fly-in you prefer to attend so we can advise others who may be undecided.

We will be giving forums on Sky Pup-type design and construction at both fly-ins, so come prepared to ask lots of good questions. We can’t wait to see some Pups flying formation in the fly-by pattern!

Building Tips

The following are suggestions and tips which have been sent to us by Sky Pup builders. Please send us any others you have found to be helpful.

1. One builder reported an alternate method of attaching the wing rib caps to the D-skins on assembly. Rather than using nailing strips (or staples) to hold the forward edge of each cap strip in place, he simply spot-glued it with super glue. This gave an instant bond which held the cap until the remainin portion could be glued in place with epoxy or Titebond. He also mentioned that clothespins work well on the trailing edge to obtain good gluing pressure between the rib cap and the trailing edge.

2. Two people have told us that they used motorcycle-type bungee (tie-down) straps to hold the wing D-skin in place for installation. These are used with ¾” square blocks which go against the rear face of the spar, and support the metal ends of the bungee straps. Six of the straps are adequate to work each section of the D-skin.

3. Several builders have found that the difficulty of drilling the entire 4” depth of the wing attach bearing blocks without excess drill wobble and misalignment can be overcome by simply drilling the hole halfway from either side. Care must be taken in laying out the centerlines of the holes exactly before the operation, but this may be the best way to achieve good alignment with minimal effort.

4. A number of builders have told us that they made two rib templates rather than one so that they could “stack cut” the ribs all at one time. This saves time, and guarantees greater accuracy of the rib contours than the single cutting method.

5. It has been pointed out to us that many of the varieties of nylon bicycle wheels do not have the same inside hub diameter as the Troxel brand wheels use on the Pup prototype. In particular, Tuff Wheels, have a 1 1/8” inside diameter hub rather than a 1 ¼” as the plans-specified wheels have. If it is easier to obtain wheels with the smaller I.D., the axle should be changed to 1 1/8” x .095 wall minimum 4130 steel to insure adequate axle strength.

6. “SIG-BOND” a product of Sig Manufacturing, is reported to work very well on either wood-to-wood or wood-to-foam bonds. This product is an aliphatic resin, and is available from: Sig Manufacturing, Montezuma, IA 50171

Changes & Modification

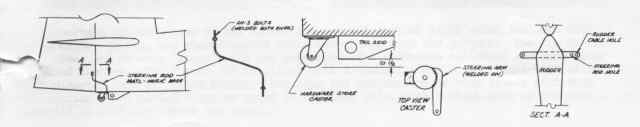

Many builders asked about adding tailwheels to their Pups. Below is the method used by Ray Macke (SN1092)

to add a steerable unit to his bird. The tail wheel is a common 2”-3” caster which has been modified by th addition of a steering arm, attached to the tail skid attach block with ¾” wood screws or bolts. Attachment with screws would provide some “tear-away” link in the installation and prevent damage to the aft fuselage structure if severe loads were encountered. Steering is accomplished through a rod attached to the rudder control horn. The tailskid attach block should be made longer than shown in the plans to extend to the forward end of the tailskid which has been moved forward. The skid remains to provide protection for the tailwheel when operating off of very soft surfaces. Thanks Ray!

Within the last two weeks, we have had conversations with builders who have finished Sky Pups with empty weights in the 240-250 lb category. In both cases, the builders stated that they had followed the plans fairly closely, and the source of the dramatic weight increase was found to be in the application of excessive varnish or paint to the fabric. One of the builders admitted to using 7 (!) gallons of varnish on the exterior fabric surface.

When finishing the Pup, only the amount of finish need to adequately seal and protect the fabric should in applied. Unlike dope, polyurethane finishes have a large percentage of non-evaporative solids which remain on the fabric after the finish is dry. Thus, the bulk of weight of each gallon will be added to the aircraft's empty weight.

There are plenty of Pups flying with empty weights in the 195-205 lb bracket.-.it can be done. Please resist the urge to ''make improvements'' or try for a show-stopping finish at the expense of extra weight.

All builders should be advised that FLYING THE SKY PUP IN EXCESS OF THE PUBLISHED GROSS WEIGHT WILL REDUCE STRUCTURAL STRENGTH MARGINS TO A DANGEROUS LEVEL

P.O. BOX 2164 * Grand Junction, CO 81502 * (303) 245-3899

SKY PUP NEWS

Newsletter #2 January, 1984

Kansas Sky Pup Flying

Miscellaneous

Building Tips

Changes & Modifications

-------------------------------------------------

SKY PUP NEWS is a quarterly newsletter for builders of the Sport Flight “Sky Pup”. Th purpose of the newsletter is to make builders aware of revisions, suggestions and ideas whic are brought to our attention. We solicit your input in the form of photos, ideas, and time o money-saving tips. Please share your progress and comments by sending them to Sport Flight, c/o NEWSLETTER.

Subscriptions to SKY PUP NEWS are $12.00/year (foreign please add $6.00, Canadian pleas add $2.00). All subscriptions are based on a calendar year, i.e. not from date ordered. Fo example, if you order a subscription in June of 1984, you will receive the January and April 1984 issues immediately, and the July and October issues when they are printed. This will insure that subscribers will receive all information which was included during that year’ newsletters.

Please use your plans Serial Number in all correspondence with Sport Flight. Thank you!

Kansas Sky Pup Flying

Allen Scott of Neodosha, Kansas recently completed and test flew his Sky Pup, SN1354. Allen reports that he spent 400 hours on the project between 5-28-83 and 12-4-83, and finished his bird for a total airframe cost of $1100. Allen’s Pup is very much “per plans” as evidenced in the photos below.

The Cuyuna 215 engine was purchased from a dealer-friend for near cost, and Allen carved his own propeller which is working very nicely. He noted the biggest problems encountered during construction was selection of wood and availability of desired fabric colors. It seems that color selections in the fabric stores vary from season to season—bright colors are most easily found during spring and summer, while “earth-tone” colors are more available in fall and winter. Overall, Allen says, “Construction itself was fun, with no real slow spots to get hung up on”.

With regard to flying the Pup, Allen reports a first flight date of 12-12-83. He had some exhaust tuning problems on the first outing which he quickly cleared up. “The Pup handles perfectly in the air and on the ground,” says Allen. “It’s the easiest flying plane ever. Never had to do thing to it after the first flight. But the most delightful thing of all is the landing—just lands itself!”

Allen is contemplating fiberglassing the perimeter of the hole in the cockpit floor because he keeps catching his feet on the edges. He glassed the area under the pilot’s heels for extra wear protection. Allen is about 6’3” and 190 lbs and says the cockpit of the Pup is “just a little cramped”.

Miscellaneous

Sport Flight is currently testing the new tractor version of the ULTRA-PROP by Competition Aircraft. As soon as the zero-degree weather and snow subside long enough to allow completion of the testing, Sport Flight will be able to supply these propellers to builders. Initial test results look very promising, and the ULTRA-PROP should be a boon to builders since th pitch can be changed to suit altitude and temperature conditions for different locales. Pleas allow us about three more weeks of testing time before inquiring about the ULTRA-PROP.

Aircraft Spruce and Specialty is now an authorized distributor of Sky Pup materials kits and hardware. Please contact them directly for pricing information at:

Aircraft Spruce and Specialty Co.

Box 424

Fullerton, CA 92632

(714) 870-7551

Always specify that you are building a Sky Pup when ordering materials from them.

Word has it that ROTAX will soon be introducing a new “free air” version of their popular Model 277 engine. This engine is designed to operate without a cooling fan by the addition of extra fin area, and should work nicely on tractor-type ultralights, such as the Pup. This development is important since the present 277 is quite heavy for the Pup and the new one should be significantly lighter.

Building Tips

The following are more suggestions and tips which have been sent to us by Sky Pup builders. Please send us any others you have found to be helpful.

1. It has been found that WELDWOOD brand latex contact cement is unsatisfactory for us in the fabric covering process. This cement dries to a very unsightly yellowish color, and seems to always leave a very bumpy texture to the surface. ELMERS brand (as called out in the plans) is the best cement for the purpose, with KINGCO (as supplied by Wicks) running a close second.

2. Many builders are painting the foam areas (such as fuselage sides and sides of wing ribs) with ordinary latex house paint prior to fabric attachment. This paint will help provide a fuel barrier, and should offer better protection against damage by ultraviolet than regular polyurethane varnishes. As an additional note, one builder has reported the existence of a clear polyurethane varnish which is labeled as having some type of UV barrier in it. Sounds good, but we haven’t seen any of it yet.

3. Rather than using an iron or heat gun for shrinking the fabric after attachment to the airframe, one builder says that he used a 250 watt heat lamp (5” diameter face) for the job.

4. Another builder has informed us that #7 Plymouth rubber bands are the perfect size and tension for holding the plywood D-skins tightly against the nose ribs during the leading edge skinning process. These should be available from an office supply store.

5. Several builders have noted that they have used a band saw to cut the foam component of their Pups to shape (espec. wing ribs). For those builders who have access to a band saw, this may take less time than setting up a hot-wire. The major difficulty to this method is preventing damage to the template by the saw blade. Guide blocks or blade with very little “set” in the teeth seem to be good solutions.

6. It seems that Dow blue Styrofoam is not shipped to regions west of the Rockies in full 4’x 8’ sheets. 2’ x 8’ sheets are the common size out west, but everyone we’ve heard from says they’re easier to work with anyway.

7. An excellent idea for holding templates in place on the foam parts during the cutting operations is the use of double-faced tape. This “carpet” tape is very inexpensive, and makes a lot more sense than staking the templates to the foam with shingle nails, etc. I would seem especially superior to other methods when using the spar caps as the hotwire guides for the foam cores. Once again, “wish we’d thought of it”!

Changes & Modifications

Many builders have asked about the conversion of the Pup to three-axis control by the addition of spoilers, spoilerons, or ailerons. Since the Pup was designed from the beginning to be a two axis machine, several features of the aircraft are tailored specifically to produce roll response through rudder input, and therefore preclude the easy addition of these extra lateral control devices.

The large amount of dihedral in the Pup’s wings (which is needed to produce a rolling momentum when the aircraft is yawed) would be undesirable for a machine with ailerons. And, the dihedral angle is used to gain spar depth at the wing root for additional strength with little weight. Decreasing the dihedral angle would require a complete re-thinking of the wing structure.

Torsional loads on the wing due to the deployment of a control surface can be significant, and were not part of the design criteria of the Pup. The wing would require additional torsional stiffness and strength if these controls were to be added. This would mean adding diagonal ribs or a rear spar and revising the fuselage and joint attachments.

The argument in favor of three-axis control is, of course, that two-axis will not provide adequate roll control in some situations. While there are some ultralights which utilize the third axis to their benefit, the majority of the three-axis machines are the result of market pressure by “conventional” pilots, i.e. the guys who want to be able to wiggle the stick sideways and see something on the wing move. Within the boundaries already posed by the mandatory low stalling and top speeds of the ultralight, we feel that two-axis control is a very effective and logical solution to the rolling problem. It offers substantial savings in weight, building time, cost, and structural complexity without handicapping” the pilot’s control of the airplane. People who have flown Sky Pups remark favorably about the roll authority of the aircraft.

So…adding roll control devices to the Pup is not impossible, but it is more involved than it might first appear. This is true of almost any change which affects the structure or aerodynamic characteristics of an aircraft. Please allow us an opportunity to review and trouble shoot changes you may be considering before you implement them.

We will try to devote a portion of each newsletter to approved changes and modifications in the future. Let us know which ones you’d most like to hear about.

SKY PUP NEWS

Newsletter No. 1 October, 1983

Sky Pups Take To The Air

Plans Updates

Changes & Modifications

Building Tips

-------------------------------------------------

This newsletter is the first in a series which will be written on a quarterly basis to update Skypup builders and make them aware of revisions, suggestions, and ideas which are brought to our attention. Since the newsletter should suit the needs of you, the builder, we constantly solicit your input in the form of photos, ideas, and time or money-saving tips. If you discover a quicker, easier, or less costly way of getting your Sky Pup into the air, please share it with your fellow builders by sending it to Sport Flight, c/o NEWSLETTER.

Since the price of the Sky Pup did not include a margin for newsletter service, we cannot provide it free of charge. This first issue is being sent for free to give you an idea of what type of material and information will be included in upcoming issues of the newsletter. Subscriptions for the newsletter will be $12.00 per year foreign please add $6.00, Canadian please add $2.00). A year subscription will include four issues, and the newsletter will continue for as long as a reasonable demand exists.

Sky Pups Take To The Air

Word of plans-built Sky Pups being finished and flown in various places is beginning to spread. Please let us know the status of your projects, and dates of completion and first flight. We are keeping a Sky Pup scrapbook of builder projects, and can only include information about your Pup if you send it.

Ray Macke, of Marissa, Illinois, has been flying his Sky Pup, SN 1092, for quite some time now. He reports good handling characteristics and performance, as well as good overall satisfaction with the project. Ray’s Pup, which is shown in the photo below, sports a few extras, including: windshield, instruments, and steerable tailwheel. The colors are medium blue and light orange —very nice! Ray says his total airframe cost was just under $750, and the total cost to build (including the extras) was $1500. Ray was able to buy a used engine with 6 hours running time for about $600.

We’ll be including pictures of other Pups in upcoming issues of the newsletter, so keep up posted on your progress. We’re looking forward to seeing large litters of Pups at some of the fly-ins next spring.

Plans Updates

Since the release of the first printing of Sky Pup construction plans, a small number of omissions and needed corrections has been brought to our attention. The following updates all apply to plans sets with Serial Numbers between 1000 and 2000. Item 1 applies to all Serial Numbers .

1. The material for the wing spar caps is Douglas Fir. Some builders who have already constructed their spars using Sitka Spruce may leave them as they are. Any new construction should utilize fir because of its strength advantage. Builders who have spruce spar caps should be aware that their spars have static strengths approximately 15% less than that for spars with fir caps.

2. The zipper panel, which is shown in the Fuselage Details sheet of the plans drawings, should be deleted. Experience with the prototype Pup has shown that the zipper is too prone to clogging and jamming to provide satisfactory service. The prototype is currently being operated with the floor hole open, but Velcro or upholstery snaps would be preferable to the zipper, if closing of the hole is desired.

3. Sheet 9 of the drawings shows one intermediate nose rib between the wing joint and the fuselage side. The photo on page 14 of the construction text shows two intermediate nose ribs for that portion of the centersection. The drawing should be changed to agree with the photo, so that two nose ribs should be equally spaced between the joint and the fuselage side. No remedial action is required for builders who have already completed centersections with only one intermediate nose rib.

4. A material callout for the diagonal member extending between the aft end of the engine mount board and the bottom of the lower engine bearer (see Section CC-CC, sheet 13 of the drawings) should be added. This member is to be ¼ by ¾ fir or spruce. Note that the member is really made of two pieces (per side) that are interrupted by the upper engine bearer. Also, the fuselage side-foam ends at the aft face of this member.

5. In order to allow the airframe to “breathe” and release moisture which could become entrapped, vent holes should be added after the fabric and finishing processes are complete. The vent holes should be from 1/8 to 3/16” in diameter, and should be located at the lowest point (where water would collect) of any sealed bay or compartment. The holes should be in the lower surfaces only, and are most easily made by melting through the fabric with a round-tipped soldering iron. The iron will melt the fabric edges, with the benefit of preventing any subsequent unraveling or fraying around the periphery of the hole.

Changes & Modifications

In corresponding with builders around the country and around the world, it has become apparent that some confusion exists concerning the design envelope of the Sky Pup.

The Pup is a carefully conceived and designed flying machine. Since it was designed and flown before the release of FAR Part 103, it was impossible to anticipate the exact requirements which would have to be met to maintain ultralight status. Fortunately, our “gut-feelings” about the outcome of the FAA rulemaking were conservative, and the Pup had no problem qualifying as a legal ultralight. Had we known the eventual outcome of Part 103, however, some parameters of the Pup would have been selected differently.

Although the Sky Pup’s empty weight is far below the specified legal maximum of 254 lbs, the gross weight which was used for stress analysis throughout the design process is the vital number with regard to structural integrity. Sky Pups must be built and operated within the specified design limits of speed and weight in order to keep the loads at a safe level. The addition of larger or heavier engines, or the addition of equipment which would render the aircraft above the gross weight, or capable of speeds in excess of the specified limits, is dangerous, and should be avoided religiously. Resist the urge to modify the aircraft without consulting with us first about the change. Some slight modifications may be allowable, but do not try to make the Pup into something it was never intended to be. It could prove disastrous.

The “design” or “ultimate” load factors (the terms are interchangeable in the aircraft industry) specified for the Pup, represent optimum failure load levels, not load levels which may be achieved in flight. The “limit” load factors used in establishing the design are approximately 60% of the design load factors, and represent the loads that could be reached at some time in the normal life of the aircraft.

The Sky Pup is NOT AEROBATIC, nor is the structure “over-designed” to allow gross margins for poor building technique or operation outside the design speeds and weights listed in the plans. Building and flying “by the book” will reward you with many years of safe, fun flying. If you have a change or question regarding structural integrity, please contact us and allow us a chance to review the idea before incorporating it.

Building Tips

The following are some suggestions and tips which have been submitted to us by Sky Pup builders. Please feel free to send us any others you have found to be helpful.

1. An alternate method of attaching the fabric to the airframe has been mentioned by several builders with model airplane building backgrounds. Rather than applying the fabric while the contact cement is wet, these builders recommend applying two full coats of latex contact cement and allowing them to dry completely. The fabric is then layed onto the surface and finger pressure is used to “tack” it down into place. When the fabric is positioned as desired and free of wrinkles, a third coat of cement is applied through the fabric from the outside. This coat softens the original coats and allows the fabric to be cemented without the hassle of working the fabric over wet cement.

2. Many builders have suggested using the wood spar caps as the hot-wiring guides for the foam webs. This method could be used on wing and empennage spars, and seems so obvious that we’re ashamed to tell the method we used on constructing the prototype spars.

3. One builder stated that T-pins (like are commonly used in aircraft fabric work) are very handy for obtaining a good joint between the plywood D-skins and the foam nose ribs. The pins are inserted through the plywood at an angle to provide the desired clamping action. These pins are used in addition to the methods described in the construction text.

4. Several builders have pointed out that there are commercial adhesives for foam which may be used when laminating foam to form a spar core. Some of these can be cut with a hot-wire, so that the intermediate step of spot-bonding the pieces until after they are cut is eliminated. Be sure that any adhesive chosen will maintain adequate strength (failure in the foam—not in the bond line) in prolonged exposure to a moist environment.

5. When ordering plywood for your Pup project, please note the significant price difference between “inch”-dimensioned plywood and metric. Apparently metric plywood is not domestic, and is therefore 40-50% less expensive, while maintaining the same strength properties.

Sky Pup News

Newsletter No. 5 October, 1984

More Pups Flying

Building Tips

Miscellaneous

-------------------------------------------------

SKY PUP NEWS is a quarterly newsletter for builders of the Sport Flight “Sky Pup”. The purpose of the newsletter is to make builders aware of revisions, suggestions and ideas which are brought to our attention. We solicit your input in the form of photos, ideas, and time or money-saving tips. Please share your progress and comments by sending them to Sport Flight, c/o NEWSLETTER.

Subscriptions to SKY PUP NEWS are $12.00/year (foreign add $6.00, Canadian add $2.00). All subscription are based on a calendar year, i.e. not from date ordered. Please use your plans Serial Number in all correspondence with Sport Flight, and specify which calendar year your subscription fee is for.

More Pups Flying

Because of the increasing number of builders who are sending photos and information about their Pups, we have decided to try and feature more than one in each issue. This issue features four Pups with brief descriptions of each based on the builders’ comments. We’d like to thank these builders for sharing their photos with the readership, and encourage others to continue to contribute material when possible.

The Pup below (SN 1307) was built by Regis Castonguay of Charny, Quebec and is (to our knowledge) the first Pup to fly in Canada. Note the Canadian registration on the vertical tail and the “jazzy” trim scheme. Regis says that the first flight was so exciting (45 min!) that he forgot about the temporary small fuel tank and ran out of gas. The forced landing was uneventful, and didn’t stop him from flying for long.

The Pup seen in the photos at the top of the next page (SN 1984) was built by Dave Haning and Bill Doty of Sidney, IA. Since Bill owns a body shop, we weren’t too surprised to see a few pin-stripes accenting the finish on this one. Engine is a Rotax 277, and the builders report very good performance. Two people have made their first solo flights in this machine without any problem. Unusual features include a leaf-type tail-spring an a Second Chantz

ballistic chute.

Bill and Dave called late one night to say that they had accidentally gotten the spar caps reversed! A little rework was required before proceeding, but the results look great.

Bill Mathis of Birmingham, AL, built the Pup shown in the photos immediately above (SN 1135) and report nice handling and good performance. Power is the Rotax engine with Culver prop, and the bird is pretty much “per plans” except for a few mods that Bill incorporated. One major change was the installation of a three gallon fuel tank in the leading edge D-cell of the center-section. Colors are red on the fuselage and leading edges, with medium blue on the control surfaces and aft portions of the wings.

Dave Beres of Walla Walla, WA, exhibited extremely good taste by covering his Pup with red and yellow (just like our prototype!). Dave’s Pup (SN 1941) has some interesting mods, as shown in the photos below. The left photo shows an installation of two chain saw engines for taxi and ground work (although Dave said they did manage to get the Pup airborne). At right is the “on purpose” installation of a Yamaha engine. Note the lowprofile wheels and simple windshield. Dave has been flying for 17 years and says the Pup “handles nicer than anything he’s ever flown”. ‘Nuff said.

Building Tips

The following are some of the suggestions and tips which have been sent to us by Sky Pup builders. Please send us any others you have found to be helpful.

1. Two builders with R/C modeling experience have informed us that epoxy paints (no brand named) are excellent for fuel-proofing foam. Be sure to test any paint on a scrap of foam before applying it to the airframe.

2. A time-saving tip for making the steel wing attach fittings is to take the stock sheet to someone in you area and have it sheared into strips before doing any cutting. This can usually be done by a fabrication shop for a few dollars, and saves a lot of hacksaw blades as well as time. Be sure to have the strip made a little over-size to allow for finish trimming.

3. Many builders report that acetone is the best all-around solvent for cleaning epoxy from brushes an tools. They recommend purchasing a gallon before starting the project so that it’s always on hand.

4. One builder told us that he used 3M “FASTBOND 30” for attaching the fabric to his Pup. He was forced to look for alternatives since he could not obtain Elmers latex contact cement locally. He says that FASTBOND 30 is superior to all other brands he tested and that its ease of workability cut the covering time by 2/3’s!

Miscellaneous

As this issue of the ‘NEWS goes to the printer, the FAA is about to hand down their findings on the successfulness of Part 103. Some additional regulation of ultralights is expected, but our inside source say that homebuilt ultralights will be little affected. We all need to pull together to keep our sport as safe a possible, yet as free from governmental regulation as we can. Contact your lawmaking representatives and le them know your views.

We are no longer recommending Titebond-type glues to builders starting Pup projects. Those who have completed aircraft using these glues should not be alarmed—our decision is made on the basis that it is easier for the novice to obtain good structural joints using epoxy or resin bonding agents. The epoxies are better for use in humid climates since they are truly waterproof while the Titebond-type glues are only water resistant.

An overwhelming number of people have asked us about the possibility of fitting floats to the Sky Pup. Since we live in an extremely arid area of the country, we would have to travel quite a ways just to try them out. We recognize that many of you live in places where float flying would be very practical and appealing, and if we undertake a new ultralight design, this will certainly have to be one of our first design criteria. We strongly discourage any Pup builders from attempting to convert their birds to floats since this would further limit the payload capability. Even the most careful installation would add 40 lb to the empty weight (not to mention the hassle of trying to build “hard” attach points in the fuselage) and render the Pup useful only to someone of extremely light weight.

Some builders have neglected to taper the wing attach fittings as shown in the plans, thinking that they were tapered only for reasons of weight savings. The taper of the fittings insures equal load distribution between the bolts in the wing, and is especially important for fatigue life of the parts.

This issue marks the first anniversary of the SKY PUP NEWS. We’ve had fun putting it together, and stated in the first issue that we would continue the NEWS as long as “reasonable demand existed”. We’re happy t report that the participation level has been high, and that the number of subscribers continues to increase each week. We want the newsletter to serve the builders, and constantly solicit not only material fo publication, but comments on what type of material is most interesting and helpful. If you have questions about particular subjects that you would like to see addressed in future issues, let us know. We’ll do our best to incorporate changes that will increase the effectiveness of the newsletter. Since this is the last issue for ’84, don’t forget to subscribe for ’85 soon!

Original Newsletters edited by Sport Flight Engineering, electronic edition compiled by Edwin Lelieveld and Roger Ford.